We all use paint in the home, but rarely do we take the time to think about where it actually comes from.

In this article, we will explore the different components that make up paint, the manufacturing process and the by-products created. We also explore how the Community RePaint Network prevents paint wastage by selling reusable paint in the community. We hope that this information will allow you to make a more informed decision when choosing which paint to purchase for your future projects.

What does paint consist of?

Paint is typically made up of four main components: resin, additives, solvent and pigments. Each has an important purpose which we will explore in more detail below.

- Pigments give paint its colour. The basic white pigment typically used is titanium dioxide, and other pigments that add colour include iron oxide and metallic salts for example[1].

- Resin is used in paint to hold all the pigments together and help the paint dry. You can get both natural (e.g. linseed oil, soybean oil) and synthetic (e.g. acrylics, epoxies) resins[1].

- Additives act as fillers (e.g. calcium carbonate[1]) and can sometimes act as anti-fungicidal agents.

- Solvents[2] or water-based are either chemical-based liquids (e.g. alcohols, acetone[1]) or water-based that make paint easier to apply to surfaces.

Image copyright Community RePaint Network

Image copyright Community RePaint Network

How is paint made?

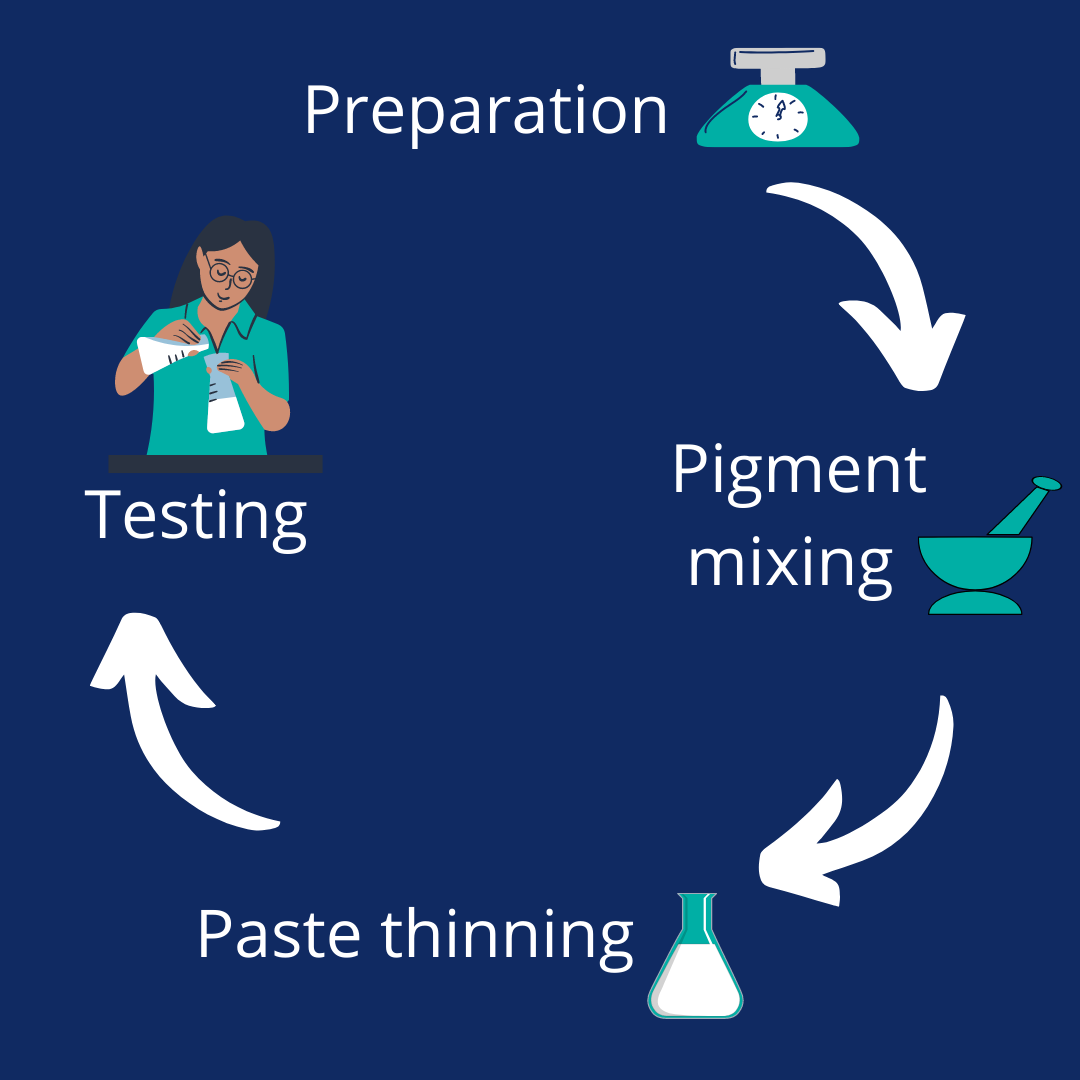

There are four main stages in the paint manufacturing process which have been simplified below:

- Preparation – this involves measuring all the ingredients and making a paste.

- Pigment dispersion and mixing – the pigment powder is broken down by the resin and additives. The ingredients are then mixed in paint mixing machines to combine and disperse the pigments.

- Thinning the paste – additional solvent is added to the mixture to give it the correct consistency.

- Testing – the final stage is testing the paint prior to containing, to ensure it has the correct viscosity[3] and appearance.

Image copyright Community RePaint Network

Image copyright Community RePaint Network

By-products of the paint manufacturing process

As with any manufacturing process, the paint industry produces a range of by-products during the process. Paint manufacturers have systems in place to help reduce and prevent the waste released into the environment, which we have summarised in the table below.

| By-product | Description | System implemented |

| Volatile organic compounds (VOCs) | VOCs are a group of carbon-based chemicals that are emitted as gases from certain solids or liquids[4]. | To reduce emissions, manufacturers implement control techniques including condensers, absorbers, afterburners and storage tanks[5]. |

| Wastewater | Wastewater is any water that has been contaminated in the manufacturing process. | Large paint manufacturer will have an in-house wastewater treatment facility that treats all liquids generated on-site[1]. |

| Waste solvents | Solvents are used to clean the manufacturing equipment in between batches of paint. It is this washing process that results in solvent wastage[1]. | The recovery and reuse of these solvents would reduce the amount of solvents disposed as waste[6]. |

| Sludge | A combination of left-over chemicals and paint during the manufacturing process. | Can be retrieved and used as fillers in other industrial products[7]. Although it is often incinerated as hazardous waste[7]. |

Saving paint from the waste stream

So now you know a little bit more about what paint is made of and how it is made, did you know that an estimated 50 million litres of the 320 million litres of paint sold in the UK each year go to waste? This paint is either thrown away or stored in homes or garages despite over 50% of it still being usable.

Community RePaint is a UK wide paint reuse network, sponsored by Dulux, that aims to collect this leftover paint and redistribute it to benefit individuals, families, communities and charities in need at an affordable cost.

Buying leftover, perfectly reusable paint from a Community RePaint scheme can reduce your global footprint by reducing the need to manufacture new paint. If you have leftover paint from your household, find your nearest drop-off point here, where it will be collected by a scheme that will reuse it. If you are a manufacturer, retailer, decorator or local company with leftover paint, please contact us for further information on how we can reuse your paint.

We sell a range of different paint brands, finishes and colours, call us in advance of your visit to see if we have what you are looking for in stock.

————————————–

- [1] http://www.madehow.com/Volume-1/Paint.html#ixzz6mYaD3wxJ

- [2] The term ‘solvent’ is applied to a large number of chemical substances which are used to dissolve or dilute other substances or materials. https://www.ilo.org/wcmsp5/groups/public/—americas/—ro-lima/—sro-port_of_spain/documents/presentation/wcms_250196.pdf

- [3] Viscosity of often referred to as the thickness of a fluid. https://www.rheosense.com/what-is-viscosity

- [4] https://www.envirovent.com/blog/what-are-vocs-volatile-organic-compounds/

- [5] https://bit.ly/3dCujd3

- [6] https://bit.ly/3eiKQlD

- [7] https://bit.ly/2QGYBTd